Non-Woven, Needle-Punched Fabrics & Felts: Face Structured Textiles

Application examples: Consumer/Recreation

- Felts for garments & crafts

- Column Wrap

- Wall Covering

- Putting Green

- RV Headliner

- Trailer Bunk

- Carpet Tile

- Carpet Underlay

- Patterned Runners

- Loop for Hook & Loop

Application examples: Industrial/Medical

- Walk-off Mats

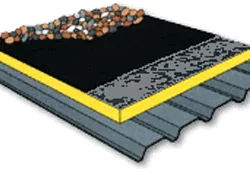

- Membrane Roof Slip Sheet

- Pond Liner Slip Sheet

- Epoxy Roller

- Filtration, Drainage

- Substrates, Scrims

- Anti-Friction

- Abrasion Prevention

- Cast Wrap

Application examples: Automotive

- Customers: General Motors, Ford, Chrysler, Navistar, Nissan and Hyundai.

- Processes: Flat punch, Velour, DiLour, Die Cut parts & blanks, light assembly & PSA lamination

- Components supplied to: cut & sew, adhesive molding, edge-wrap & Compression molding operations

- Supplies components for the following applications:

- Seat Back & Toe Rail

- Rear Package Tray

- Console

- Door Trim

- Trunk Trim

- Arm Rest

- Head Rest

- Spare Tire Cover

- Lumbar Support

- Seat Frame/Foam Separation

- Load Floor Carpet

- Glove & Utility Tray Liner

Features of Needle-punch, Engineered Fabrics

- OEM Custom Constructions and Colors

- Lightweight

- Sustainable

- Cut-able

- Moldable

- No Binding Required

- Fade Resistant

- Stain and Mildew Resistant

- Will not Fray or Unravel

- Die Cutting Services Available

- Secondary Operations Available

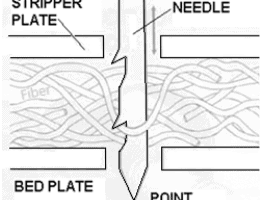

Needle-punch Technology

- Needle-punch, non-woven fabric production involves the binding of fibers through random mechanical interlocking.

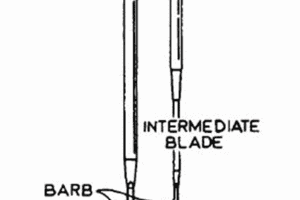

- Needle-punching uses barbed needles to interlock the web layers of fibers with the layers around them.

- The density, loft and function of the fabric is controlled by needle density, penetration depth, gauge, barb shape & density, point type and blade shape (pinch blade, star blade, conical) and the fiber and web that they interlock.

- This is a pure mechanical bond; no water, air, heat or chemicals are necessary unless the finished product application requires it.

- The products made by the needle-punch bonding method are 3-dimensional with excellent wear, flexibility, drainage and air permeability characteristics.

Process Technology

- Bales of Fiber: Polyester, Polypropylene, Rayon, Acrylic

- Fiber opening & Mixing

- Fiber Hopper

- Carding

- Cross lapping

- Web Feeding

- Pre-needling (pre-punching)

- Flat Finish Needle-punching

- DiLour Finish Needle-punching

- Calendar & Heat Treating

- Slitting, Edge Trimming & Winding

- Die cutting, laminating & Finishing

Executive Summary

- OEM product lines include Needle-punch flat and 3-D patterned fabrics for Medical, Marine, Roofing, Recreational Vehicle, Wall Covering, Flooring & Matting, Industrial, Construction, Automotive and Consumer applications.

- Focus on continuing to improve its existing Needle-punch technologies and to Engineer solutions that have not previously benefitted from the inherent cost savings and flexibility of Needle-punching.

- As a Solutions Innovator, structured to produce short runs of Needle-punch fabrics in addition to larger volumes typically characteristic of the needs of Automotive, Flooring and Construction OEMs.

Facilities and Capabilities

- warehouse and production facilities totaling 90,000 square feet

- 6+ production lines

- Maximum width up to 180 inches (15 feet)

- Staple fiber lengths from 1.5 to 4.0 inch

- Denier from 3 To 200

- Weights from 180 GSM

- Loft from 2mm Flat punch to 12mm Velour/DiLour

- Loop and Fiber end

- Thermal Bonding, 3-D Patterning, PSA application and Die Cutting

- Fully staffed and equipped, Quality Control facility

Quality Control

- Quality Manual and Procedures

- ISO 9001:2015

- Statistical Trending at each operation

- QC Lab (600 square feet)

- Dedicated QC Personnel

Get In Touch

Contact us to see how we can help meet your technical product requirements!